| Machine tool industry-Machine Enclosures | |

| Aircraft industry | |

| Energy sector | |

| Power Distribution Panel | |

| Oil Refinery | |

| Tube Sheet fabrication | |

| Control Panel | |

| Agricultural Equipments | |

| Filters for Cement Plant | |

| Signboards | |

| Food Processing Industries | |

| Control Panel | |

| General Fabrication |

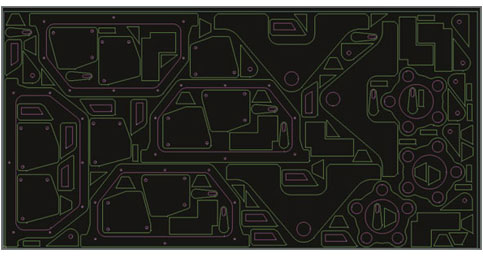

| Maximum utilization of sheet | |

| Clean burr free edges eliminates secondary operations such as burr removal etc. | |

| Multiple part nesting | |

| Cost effectiveall machining done in one set up and no special tooling required | |

| Prototype to production quantities | |

| Highly complex to simple shapes | |

| Very accurate cuttingparts fill together with precision so end products are easier to assemble | |

| Modifications are easy | |

| Fast turnaround UPTO 8MM | |

| Efficient part nesting capability Due to narrow kerf width and programming flexibility | |

| Fast, inexpensive prototyping Due to little or no hard tooling | |

| Rapid design changes Due to narrow kerf width | |

| Cost competitive Due to low fixture costs, high feed rates, and minimal downtime | |

| Proven application | |

| No part distortion - Due to small Heat Affected Zone(HAZ) |